95XXXXXX26

Send MessageStreet Address: Dabaspet

City: Bangalore

Province/State: Karnataka

Country: India

Business Details: Hind High Vacuum (HHV) is India’s premier thin film and vacuum technology company with over 50 years of expertise in the design and manufacture of high vacuum equipment for optical, decorative, functional coatings and astronomical telescope mirrors. HHV also manufactures special purpose vacuum equipment for complex metallurgical applications. HHV’s Thin Films and Optics division is a leading manufacturer of high precision optical components and thin film coatings. It’s manufacturing unit includes facilities for optical polishing, high end metrology, thin film coatings and testing capabilities. HHV manufactures dichroic coated optics, laser filters, narrow band interference filters, hybrid micro circuits, periscope prisms, thin film heaters and infrared optics for variety of applications in industrial, space and defence technologies. HHV has multiple manufacturing facilities in Bengaluru, India. These manufacturing facilities are equipped with ISO 7, ISO 8 clean rooms to manufacture and coat high precision optical components. HHV produces over 100,000 optical components every year for domestic and international markets. With sales offices in the United Kingdom and global distributor presence HHV exports its products to the USA, UK, Germany, Italy, Turkey, Switzerland, South Korea, Singapore and China. HHV maintains close collaborative links with premier research institutions such as the Indian Institute of Science, the Indian Institutes of Technology, National University of Singapore, Northwestern University and the University of Oxford. HHV has extensive working experience with India’s premier defence & space institutions such as ADA, BEL, RCI, DRDL, BARC, and ISRO. HHV is an ISO 9001:2015, ISO 14001:2015 and OSHAS 18001:2007 certified company. HHV awarded a ‘Certification of Qualification’ by the Indian Space Application Center, ISRO for its Thin Film Metalized substrates, and also received the prestigious National R&D award for the same.

Business Type: Manufacturing Sector

Keywords: UV Reflectors, Optical filters, Laser safety glasses, Laser Optics, Night Vision optics, Periscope prisms, Transparent heaters, Thin film metallized circuits, Black absorber coatings, EMI shielding coatings, AR coated Zinc sulphide domes

Office Location: Karnataka

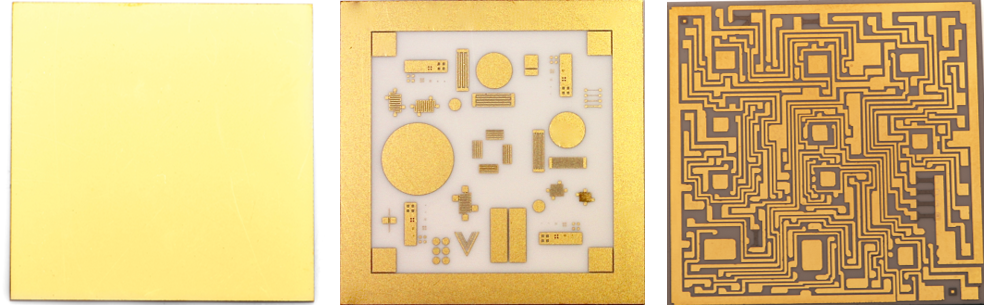

HHV’s thin film metallization process is carried out through magnetron sputtering. The deposited metal layers show superior adhesion, structural and electrical properties in comparison to non-vacuum methods. The metallization schemes start with a bonding layer of titanium-tungsten or chromium and a conductive layer of gold or copper on a ceramic substrate. For resistor applications we use tantalum-nitride (TaN) or nickel-chromium (NiCr) layers and for solderable applications nickel or copper is added to the metallization scheme. All the metal layers are deposited in a single cycle without breaking the vacuum process. The sheet resistance of TaN and NiCr layers can be tuned from 10 to 250 O/sq depending on the application. Subsequent to the metallization, the substrates are patterned in an in-house photolithography facility. We use positive photo resist to produce mask plates, For patterning, the substrates are first coated with a negative photoresist through spin coating and baked. The patterns are generated using a mask aligner and UV exposure system. The photoresist is then developed to realize the required pattern. With our in-house direct laser writing facility, we can achieve resolutions of 1 micron on photomasks and our lithography facility is capable of producing patterns with 40 micron linewidths. PRODUCT FEATURES - Substrate: Alumina, Zirconia - Dimension: Up to 2*2 inches - Durability: Qualified for Space applications - Custom patterns and metallization schemes can be developed and produced on request APPLICATIONS - RF/Microwave integrated circuits - Hybrid micro circuits - SAW devices - RADAR - Thin film resistors - Reticules